It will also provide the plant with two separate rolling mills, one for wire rod and the other for rebar production, a company spokesperson confirmed to Fastmarkets.

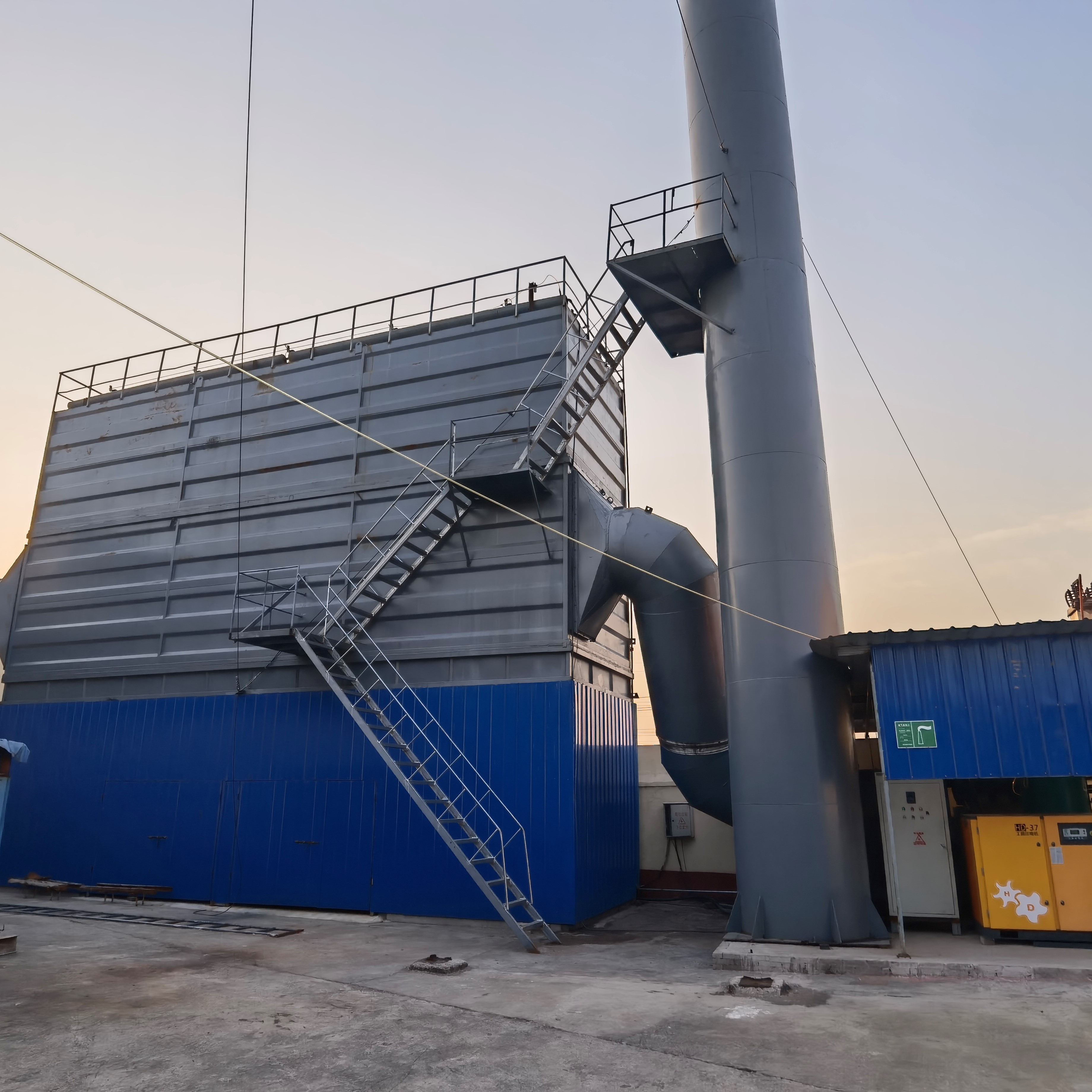

The electric-arc-furnace (EAF) long steel producer has completed the first phase of melt shop upgrades that will boost its production of wire rod, coiled and straight rebar production, according to a June 5 press release from the company. large rolling mill

“This is a doubling of rolling capacity,” a company spokesperson said on Friday June 9. “The rebar outlet will commission in the late third quarter of this year. The new reheat [plus] roughing [plus] intermediate project will commission in late 2024.”

“When everything is complete, we will have one wire rod mill capable of 800,000 tons and one rebar mill capable of 800,000 tons,” the spokesperson noted.

Optimus Steel’s investment in expanding and diversifying its rebar product offerings can also give the company improved operating margins that can help it better compete for market share for both rebar and wire rod, according to a wire rod buyer.

The wire rod buyer described the scale of improvements at the Beaumont mill from the beginning to completion as “by far the largest expansion in the domestic wire rod industry in many years.”

While the company is expanding from coiled rebar into straight rebar, when all the work is done, “Optimus mill will still have a majority of its production in wire rod versus rebar,” the wire rod buyer said.

The task of upgrading and improving the facility has been undertaken in several stages, according to Optimus Steel’s June 5 press release. It declined to provide detailed information on a breakdown of expected production by product lines.

“The Optimus Steel expansion project has been going on for some time – they announced the expansion in 2021, when wire rod prices were very high,” a trader said.

Fastmarkets’ monthly assessment for steel wire rod (low carbon) industrial quality, fob mill US was $53.00-58.00 per hundredweight ($1,060-1,160 per short ton) on May 16, down by 8.26% from $58.50-62.50 per cwt on April 18, and 9.02% lower than March 21’s $59.00-63.00 per cwt.

Prices for low-carbon wire rod are now at their lowest since July 20, 2021, when they stood at $55-57 per cwt.

In the initial round of improvements and investments completed in 2021 and 2022, Optimus “upgraded their melt shop, including a new caster which was not only remedial/mandatory, but gave them more billet supply,” the wire rod buyer said.

“A lot of the impact of their new caster and melt shop upgrades will result in them being more self-sufficient regarding billet,” the wire rod buyer said.

At the same time, however, “the expansion did not necessarily result in a massive increase in the total amount of rod they can roll, but it will mean they will roll more of their own billet versus billet that was purchased from other US mills or from imported billets,” the buyer added.

Another major upgrade – the addition of a straight rebar outlet – is scheduled to be commissioned by the end of the third quarter, according to the company notice.

The final phase of improvements, including a new reheat furnace and a roughing and intermediate project, “will be commissioned in late 2024,” according to the company’s notice.

Before the improvements and upgrades were underway, Optimus Steel’s Beaumont facility – which was purchased from Gerdau SA in 2018 for $92.5 million – had the capacity to produce wire rod of 7/31-11/16 inches and coiled rebar in sizes #3-#5.

After the completion of the rebar outlet, it will be able to add cut-length stick rebar in sizes #3-#11, according to Optimus Steel’s press release.

The wire rod buyer expects the mill “to put in a system to allow them to go back and forth from wire rod to cut-length rebars [and that capability] could displace some imported cut-length rebar tonnage, especially in the strong Texas and regional construction market, as infrastructure spending, with a strong ‘Made in the USA’ requirement, becomes a reality.”

While more wire rod and rebar capacity could theoretically act to weaken prices “to some extent,” that may not necessarily be how it plays out, according to the wire rod buyer.

Instead, he added, “a stable, reliable, competitive US rod industry could replace imports to a great extent.”

Imports are not without risks in terms of lead times and other issues, and most wire drawers would prefer to buy domestically if possible

“Imports are not without risks in terms of lead times and other issues, and most wire drawers would prefer to buy domestically if possible. As we’ve seen in the past, and as recently as 2021-2022, the demand for wire products can sometimes outrun the capacity of the aging US rod industry, leaving wire drawers no choice but to hedge with imports,” the wire rod buyer said.

“Often the market price for wire rod does not fully compensate for its higher cost of production compared to rebar,” the buyer said.

“Wire rod production involves slower production rates, more changeovers and variations by size/grade/quality levels, a more critical scrap mix, more sensitive chemistry, more stringent surface requirements, tighter diameter tolerances, and more potential for claims and rejections compared to rebar,” the steel buyer said.

A mill source agreed. “A new entrant to the rebar and wire rod market will take a lot of business” from imports, the source said.

“The cost to produce rebar is significantly less than wire rod and the price is not much lower than rod,” the source added.

Rebar provides a better yield from lower-cost scrap, while wire rod relies on higher-grade scrap and comes in more grades and sizes, requiring time-consuming changeovers in production lines and more downtime, according to the mill source.

The domestic price of rebar in the US has been declining this summer, with producers reacting to an increase in cheaper overseas material arriving on US shores.

Fastmarkets assessed steel reinforcing bar (rebar), fob mill US at $46 per cwt ($920 per short ton) on June 7, unchanged after falling to this level the prior week.

Import volumes of rebar more than doubled month on month in April, reaching 158,001 tonnes, compared with 76,844 tonnes in March, according to preliminary data from the US International Trade Administration’s steel import monitoring system (SIMA).

In April 2022, the US imported 158,000.6 tons of carbon and alloy rebar and 62,185.1 tons of carbon and alloy wire rod, according to the US Department of Commerce.

Import licensing tonnage for May was lower for carbon and alloy rebar at 66,521.8 million tons and higher for carbon and alloy wire rod at 68,569.8 million tons.

Discover 900+ prices for global metals markets

Build your personalized view of the metals markets in the Fastmarkets dashboard

reversing rolling mill Benchmark Administration Terms of Use | Privacy Notice | Modern Slavery Act | Subscription Standard Terms