How are 3D printed moulds transforming thermoforming processes with time and cost optimisation.

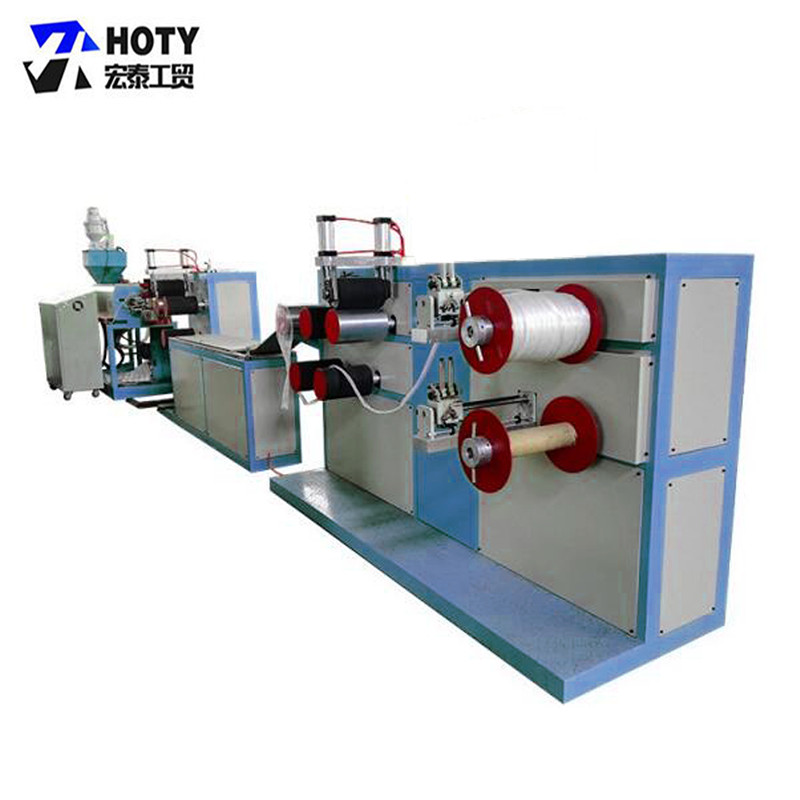

Due to supply disruptions, manufacturers are turning to additive manufacturing (AM) to help them accelerate production processes while maintaining quality and reducing costs. Many plastic thermoforming companies are now leveraging AM to assist in traditional vacuum and thermoforming processes, making them faster, more cost-efficient, and more agile. PS Foam Sheet Extrusion Machine

In conventional thermoforming processes, plastic sheet materials are shaped over moulds, often with the assistance of a vacuum, to produce the final part. The moulds can be produced in different ways, including using cast ceramics and CNC machining of metals, wood, tooling board, or hand-sculpting of wood. To create the desired shape, these subtractive processes selectively remove material from a block or billet with a spindle.

Alternatively, AM methods build the part layer by layer. This is done using an extensive range of polymers, including standard and high-performance thermoplastics, thermosets, filled and photopolymer resins, and even metals. Additively manufactured moulds offer freedom of design in comparison with conventional means. AM also increases efficiency, yielding a mould or prototype within hours or days while traditional manufacturing often necessitates weeks and months.

It’s important to consider which 3D printing technique is most suitable for the mould production. For medium- to large-scale parts, pellet extrusion has demonstrated many benefits, including the ability to optimise times, reduce the cost of mould production, and production flexibility.

Thermoplastic pellets are considered the lowest-cost raw material for AM - up to 10 times less than other printing materials, such as thermoplastic filament. In addition to material cost savings, pellet extrusion 3D printers can print moulds up to 1270 x 1270 x 1820mm (50 x 50 x 72 inches) using high-performance and high-temperature materials at speeds reaching a half metre per second.

To achieve a high-quality final part, 3D-printing production moulds for thermoforming require minimising mould distortion. Thermoforming companies such as Duo Form, for example, have validated glass-filled polycarbonate pellets as a proven material for such applications, along with carbon-fiber-filled ABS pellets and even some nylon pellet feedstocks as viable mould materials.

Several factors should be considered when selecting a pellet feedstock for AM moulds: the gauge of the final sheet being formed, the temperature requirements of the final material, and the availability and cost of the pellet feedstocks. For example, when a thinner gauge is utilised as the final formed sheet, lower temperature mould materials are acceptable, such as CF-ABS pellets. For applications that require a thicker gauge or higher temperature final sheet material, higher temperature pellet feedstocks should be used for printing the mould, such as GF-PC or filled nylon material.

Another advantage is the ability to leverage a porous surface of the printed part, allowing a vacuum to pass through a mould without having to use special tools to make the vacuum holes. According to Duo Form, the inherent porous nature of 3D-printed moulds presents a significant advantage when employing pellet-extrusion 3D printing in its mould production process. Depending on the intended final thermoformed part, it may be important to prioritise the flow of vacuum through certain zones of the mould to be able to get the desired outcome of the forming process. This goal can be accomplished by adjusting tool pathing parameters before printing.

Duo Form, a US leader in thermoforming for many industries, is making continuous efforts to innovate its processes to reduce lead times and costs, allowing the company to better serve customers and win new business. To integrate this technology into its manufacturing process, Duo Form collaborated with 3D Systems. AM offered the company more agility by 3D printing production moulds, tools, and representative samples for thermoforming and vacuum forming.

The company embarked on a project involving 3D printing a 1294 x 410 x 287mm train interior panel with the potential of reducing cost by up to 88% as well as lead time by 65%. The combination of an EXT 1270 Titan Pellet 3D printer and glass-filled polycarbonate pellets led to a major cost and time reduction. Immediate results were perceived with their subsequent first 3D-printed mould, a shower pan for recreational vehicles. The outcome was a high-quality AM mould with durability comparable to moulds produced through traditional methods. Over 1,000 shots have been pulled from the mould without notable signs of wear.

David Rheinheimer, Duo Form product development manager, says: “We have gained a lot of business with our Titan 3D printer. The turnaround time for parts, moulds, and formed parts has put us leaps and bounds above our competition.” Since implementing AM as part of its manufacturing process, Duo Form says it has won more business and now closes deals faster thanks to the speed and agility of pellet-extrusion 3D printing. In fact, when Duo Form 3D printed a sample part to present to a customer along with a quote for forming the part, the customer, impressed with the speed and ability to see the final design first, awarded the company the bid that same day. This has now become standard practice for Duo Form and brings added value to its customers.

AM is reshaping production processes and the way companies perceive them. Large-format pellet extrusion 3D printing is amongst the technologies leading the way. This advanced technology will enable industry leaders to benefit from a competitive edge with increased speed, improved cost management, and higher-quality part production.

We are only scratching the surface of the possibilities that pellet extrusion can offer in the thermoforming industry and other applications. With the ongoing evolution of innovation, AM will consistently showcase its ability to mould the future of manufacturing.

Clay Guillory is the Director, Titan at 3D Systems.

Foam Plastic Sheet Extrusion Machine © Setform Limited 2019-2024 | Privacy policy | Archive