The Enerpac PP-Series includes a total of four hydraulic power packs: two electric and two diesel powered models. These power packs are enclosed within a protective frame and feature forklift truck and vertical lift points.

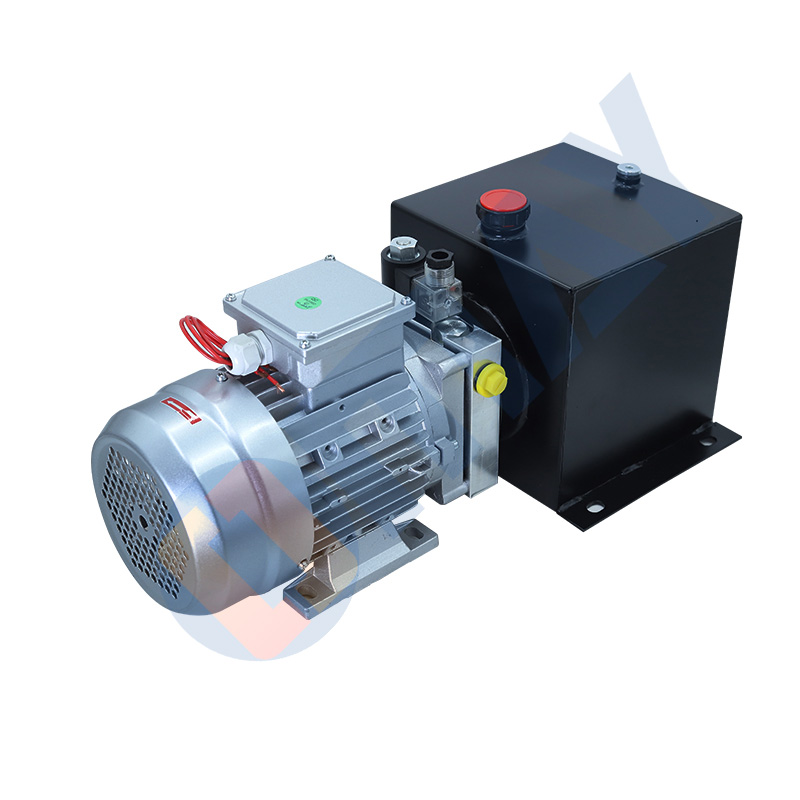

Enerpac announces the new PP-Series electric and diesel-powered power packs to supply hydraulic flow to Enerpac portable machine tools, including flange facing machines, clamshell cutters, hot tapping machines and decommissioning tools. The hydraulic power packs are compatible with other brands of portable machine tools. Hydraulic Power Pack Motor

The Enerpac PP-Series includes a total of four hydraulic power packs comprising two electric and two diesel powered models. Variable pumps within the power packs allow pressure and flow to be adjusted for specific applications. To facilitate handling and deployment, the Enerpac power packs are enclosed within a protective frame and feature forklift truck and vertical lift points.

Portable machine tool operators with access to an electric power supply can choose between the electric powered hydraulic power pack 11 or 15 kW models - each available with a choice of voltage options for use throughout the world.

Many manufacturers of hydraulic power packs provide a general-purpose control pendant as standard with each unit. To meet these different applications, the products feature a range of pendant options for specific machine tools. In addition, operator safety emergency stop buttons are provided on the power pack and the control pendant.

For working in remote locations, customers have a choice of 19 and 44 kW units. These power packs are designed for larger machine tools used for operations such as hot tapping and decommissioning.

Both the Enerpac diesel PP-Series PP19 and PP44 units are diesel powered and meet the EU Stage V and EPA tier 4 final regulations for emissions. Each includes a 50-liter diesel tank, which, in the case of the PP44, can provide up to 12 hours of run time at maximum torque. Also included in the diesel power packs is a spark arrester for safety in explosive environments.

Unlike the electric units which work with pendants to provide control, the PP19 and PP44 power packs require a separate hydraulic control panel and machine specific hose kits. The hydraulic control is connected to both the machine tool and the hydraulic power pack. The control panel houses all the controls needed for specific machine requirements. In addition, the diesel PP-Series power pack features a pressure-less switch to remove pressure and flow.

A 10-meter hose kit is supplied as standard and longer hose kits are available as accessories for single-supply, dual-supply and triple-supply applications. Triple supply hose kits allow three hydraulic motors to be connected to the power pack simultaneously. With spindle control, the operator can also select the required axis (x or y) from the pendant.

Hydraulic Power Pack Pressure Setting Machine operators choosing an Enerpac electric PP-Series power pack can also utilize an optional cart to enable positioning and storage within a workshop environment.