The use of geomembrane liners in mining applications has been well documented and tried and tested, for over 50 years now. Mining companies are constantly improving the extraction processes for recovery of minerals. As such, there is a growing demand placed on a barrier and containment system need to track these advances.

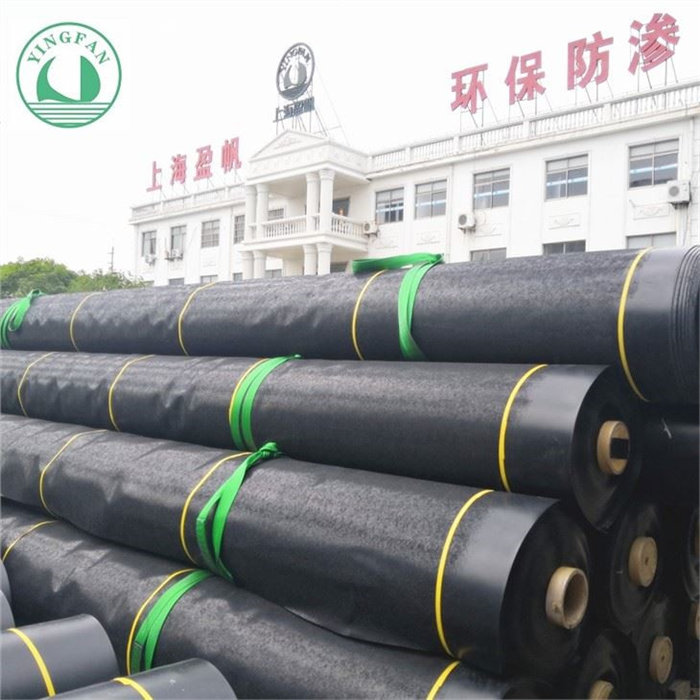

AKS Lining Systems is a modern manufacturing facility, specialising in the production of geomembrane liners specifically for the mining industry. The company has been manufacturing quality thermoplastic products since 2002 and operates within a very specialist, yet expanding market in geomembrane liners. In addition to supplying the local market as well as the SADC region it exports to more than 23 countries worldwide. Geosynthetic Clay Liner For Ponds

AKS Lining Systems has grown to be an extremely competitive global producer of thermoplastic products. It is able to achieve its competitive edge by streamlining its operations and by using technologically advanced and energy efficient equipment. Through innovation, the company is able to offer its customers comprehensive systems and complete technical support at competitive prices.

AKS’ Technical Manager, Peter Hardie, has been involved in the lining industry for 25 years and has worked on projects all over sub-Saharan Africa, and globally. Giving a short overview of their Cape Town based operation, Hardie comments: “Our manufacturing plant is situated close to the international harbour port. This allows us easy import of the high grade hexene based resins which we need for production of good quality geomembrane liners, be these High-Density Polyethylene (HDPE) or Linear Low-density Polyethylene (LLDPE). Currently the bulk of our supply programme is focused on HDPE liners. This is tried-and-tested technology and HDPE liners are specified in nearly all mining containment applications. The use of LLDPE is also growing in traction, but the broad based, high chemical resistance of HDPE still makes it the liner of choice.”

Geomembrane liners are required in all mining operations. “To be honest, I have yet to find a mine that has no geomembrane liner requirements. The use of these products is so vast and varied. The benefit which they offer in terms of environmental and groundwater protection or simply for containment of extremely high value liquids is unmatched. Geomembrane liners are installed in a wide range of applications on mines such as tailings storage, leach pads, storm water ponds, pregnant solution ponds, water harvesting to name just a few. Even a simple ‘raincoat’ application used in high rainfall tropical climates,” Hardie adds.

AKS Lining Systems is constantly making technological changes and improvements to its liner systems. “Our liners are manufactured using the Flat-die or Flat-cast extrusion process. This allows us to manufacture products with exceptional flexibility. Figures like 800% break elongation and high impact and tear resistance properties can be engineered. We are also able to offer enhanced texturing on the surface of our liners which gives the design engineers a wide range of products that can be utilised in applications with longer side slopes or steeper embankments. The textured liner effectively ‘biting’ into the soil, to offer better slope stability.

“In order to stay at the forefront of developments, we are also able to offer our clients products like Reflective liners – these are geomembranes extruded with a thin white reflective surface on the top side, reflecting the sun’s heat during installation and allowing the liner to lay flatter on site. Other products such as conductive liners offer our clients and their engineers the option of performing detailed quality control through spark testing or pinhole detection surveys. A conductive liner has a very thin electrically conductive layer extruded on its underside.

“This means that huge areas, such as in a TSF, can be checked after installation to ensure there are no pinholes and offering water tight installation. This product range also offers benefits in quality control testing in double lined pregnant solution ponds.”

Hardie adds that manufacturing in South Africa also has some challenges. “Based in South Africa and operating a large manufacturing facility like this certainly has its challenges. We have manged our risk in terms of power supply and in turn mitigated our client’s risk, by installing generators, which enable us to run the entire plant off-grid. Our electricity generating capacity is around 3,5MW. This investment in power stability has meant that we continue operations regardless of the challenges of loadshedding.

Currently we are able to produce around 1.5 million square metres of liner per month and we supply this into sub-Saharan Africa. Being a local producer has some additional benefits to our clients in terms of SADC certification. We also export our liners to 23 countries around the globe, from Mexico right through to Singapore, Vietnam, Australia and New Zealand. Our dedicated logistics and quality team ensure that every shipment is accompanied by the full range of QC certificates, Shipping or export documents to ensure a seamless delivery to site.”

AKS Lining Systems is a manufacturing facility, however its in-house sales engineers have a wealth of installation knowledge in geosynthetic fields. The company’s philosophy is to analyse customer needs and to offer them technical, hands-on advice resulting in long-lasting solutions. It also has a comprehensive in-house laboratory to test and monitor the quality of all its products and resins.

“I believe there are still very few (if any) products that can offer the versatility that a geomembrane liner can offer for the broad range of applications utilised during mining. Not only during the mining activities, but geomembrane liners then continue serving as reliable containment and environmental protection barriers long after mining activities have finished,” he concludes.

Hdpe Biaxial Geogrid © All content copyright 2017 - 2024 VUKA Group, unless specified otherwise.