A leading Spanish automotive supplier has put its third twin-sheet thermoforming line into operation for the manufacture of ducts for automobile air conditioning. The UAR 155g machine was supplied by Illig of Germany.

Lightweight and moreover flexible automotive air ducts are molded in sophisticated 3D geometries using XLPE foam and the thermoforming process on this Illig unit. Small Pyrolysis Machine

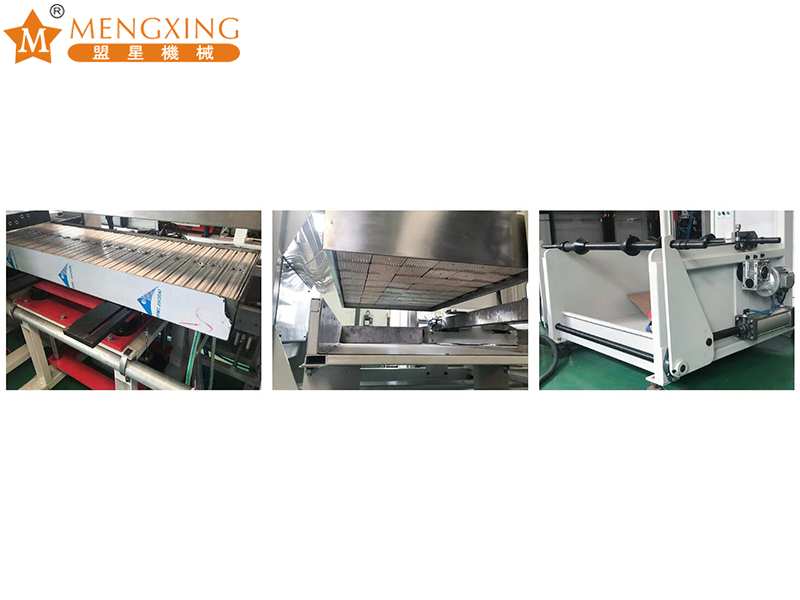

In twin-sheet thermoforming of cross-linked polyethylene (XLPE) foam, two sheets heated up to processing temperature are formed into half shells in the mold, supported by vacuum, and at the same time they are welded together on the outer contour. With the system developed by Illig; the formed parts are punched directly in the mold after the end of the cooling time. The upper mold half is equipped with extendible serrated knives. The lower mold half is equipped with grooves in which the knives interlock during punching. The punched out parts are secured by “holding bridges” and removed from the forming station. Upon removal from the thermoforming machine, only the joint areas of the air ducts have to be cut – just like blow-molded rigid ducts.

XLPE foam ducts boast several advantages compared to blow-molded, rigid PP ducts that are commonly used at present according to Illig. For example, ducts molded using XLPE foam (density of approximately 70 to 80 kg/m³ depending on the application) are not only substantially more lightweight than ducts made of solid PP (density of 900 kg/m³); among other properties they also possesses substantially lower heat conductivity and superior acoustic dampening behavior thanks to their foamed structure.

In this way the foam’s lower heat conductivity minimizes condensation of water in the air duct after switching off the air conditioning system. High elasticity and good resilience of the ducts reportedly provide further benefits, such as ease of assembly and reduction of squeaking and rattling sounds even within a compact installation space.

In the thermoforming process, XLPE sheet (thickness 3 to 4 mm) is supplied by two material roll stands and each material is heated up in the forming station to a surface temperature of up to 200 C. Subsequently the heater is rapidly removed from the forming station– in less than 3 seconds – in order to minimize cooling of the material prior to commencement of the forming process. Further, the servo drives for the upper and lower mold table are especially designed for rapid movement speeds of up to 500 mm/s, even for tools with a weight of up to 1 t per mold table.

A further benefit provided by thermoforming with twin-sheet technology versus extrusion blow molding is that multiple parts of differing dimensions and geometries can be manufactured simultaneously by utilizing a large-area tool (the UAR 155g features a forming area of up to 1450 x 1200 mm). This capability also has implication in terms of cycle time per air duct, which is naturally shorter. On these accounts, air ducts made of foam are cost competitive when compared with rigid PP blow-molded ducts– manufacturing costs per duct are in fact comparable.

New Milestone in Flexible PVC

Breaking News in Flexible Packaging January 2024

JEC Composites Innovation Awards: Finalists in Equipment, Machinery, and Heavy Industries Category

PP Thermoforming Equipment Copyright © 2024 All rights reserved. Informa Markets, a trading division of Informa PLC.